The

Problem

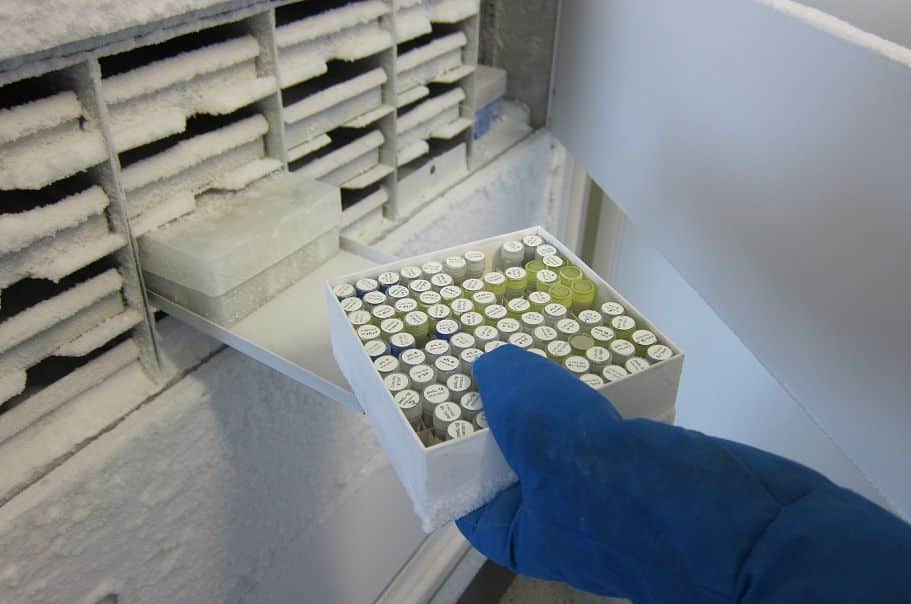

Your research samples are priceless, mission-critical assets that can be lost if not adequately protected 24/7/365 in ultra-low temperature (ULT) storage. And yet, conventional ULT freezers may be the weakest link in your sample preservation process, especially considering that compressors in nearly all ULT systems are expected to fail at some point during the life of the unit. Freezer failure can be devastating, as compromised temperatures can destroy years of work and threaten future experiments.

ULT Freezer problems are disruptive, place valuable biological samples at risk and can even hinder years of research

Ultra-low freezer failures can also hit without warning. This not only jeopardizes research sample integrity, but also requires that your team take time-intensive and disruptive measures to assure the availability of safe, backup storage. Because compressor-based ULT freezers need regular, ongoing preventive maintenance and must operate within a narrow set of ambient conditions, a lapse in meeting these requirements can also place your precious research specimens at greater risk.

Even a ULT freezer that appears operational can risk sample integrity if temperatures warm excessively during the compressors cycle off periods, slow recovery after door openings or if there are undetected warm positions within the cabinet.

The

Solution

Breakthrough technology that is better at protecting the safety and integrity of your research samples

Stirling Ultracold has developed a better, safer technology for preserving your life’s work by replacing compressor-based ULT cooling with the free-piston Stirling engine. This advanced technology addresses the failure modes of compressors in ULT systems.

Watch this quick video to learn more about the Stirling Ultracold SU780XLE upright freezer

This technology is field-proven and trusted by leading research facilities and institutions with more than 300 million cumulative hours of ULT freezer operation and over 15 years of commercial use. In that time, Stirling Ultracold customers have benefited from better overall temperature performance that protects their samples over the widest range of operating and ambient conditions, while requiring only minimal ongoing maintenance.

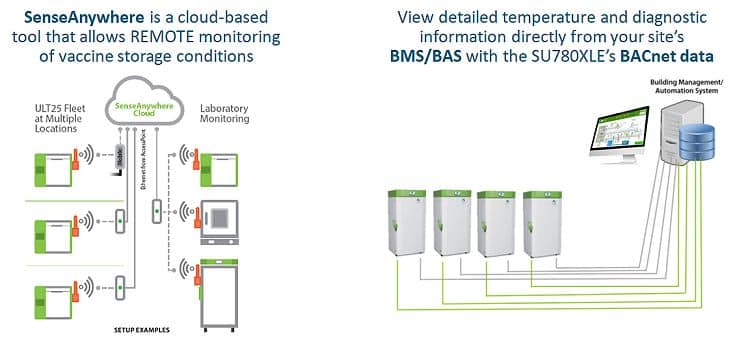

All Stirling models are available with cloud-based temperature monitoring that provides the peace of mind of knowing your samples are always safe. Our SU780XLE upright model also has an available Ethernet port that transmits data via BACnet™ protocol or MQTT onboard server for robust monitoring capabilities.

Stirling Ultracold also provides industry-leading protection and service with a 7-year warranty on the Stirling engine system, with a factory-authorized, global network of service centers.